Price: Negotiable

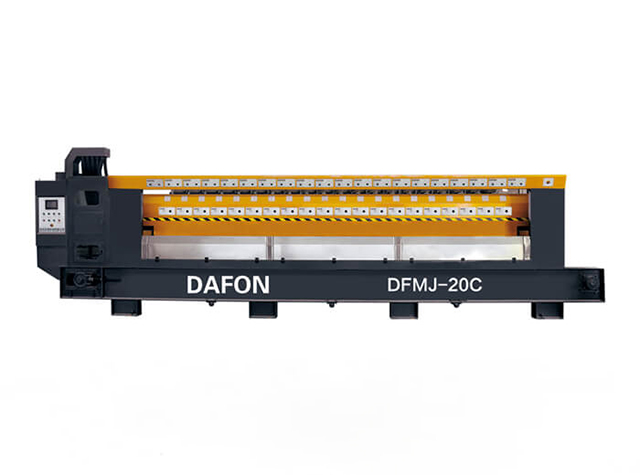

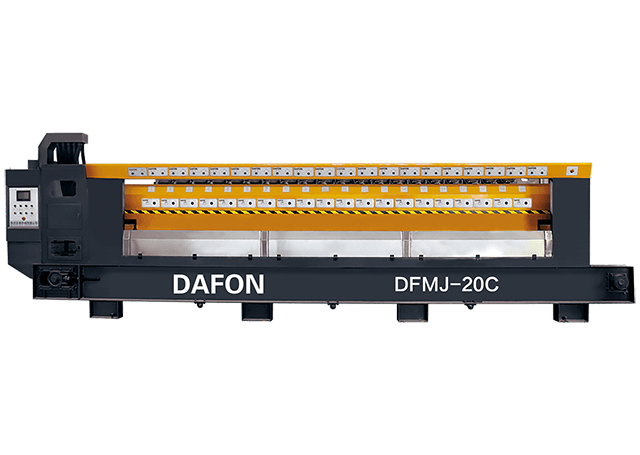

Brand Name: DAFON

Certification: CE, ISO

Model Number: DFMJ-16C-24C

Power: Depends on heads no.

Weight: Depends on head quantity

Application: Machinery & Hardware, Construction, Stone

Place of Origin: CHINA.

Trading Method: FOB/CIF/EXW Xiamen Port

Minimum Order Quantity: 1 SET

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

Introduction of granite polishing machine

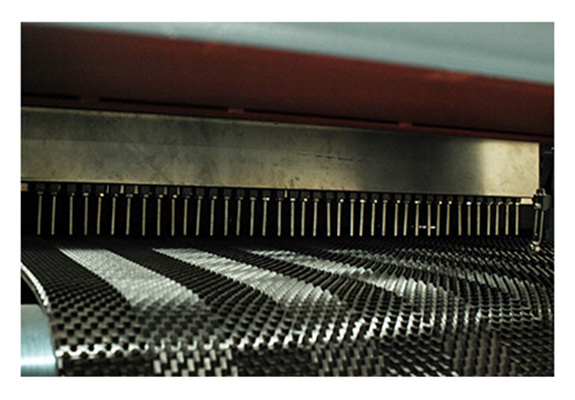

granite slab polishing machine that can polish the ground stone equipment, can be adapted to different grinding block or grinding pad, through the hanging gear or frequency change motor speed professional grinding and polishing a variety of marble, terrazzo, granite, floor tiles and other stone ground, so that the stone can regain the brightness of the factory is just

Technical Data of granite auto polish machine

|

polishing width |

300-1250mm or 2100mm available |

|

polishing thickness |

15-50mm or 50-100mm |

|

belt adv speed |

800-3700mm |

|

polishing head motor |

7.5kw/11kw/15kw |

|

total motor |

7.5kw/11kw/15kw ×Number of heads |

|

weight |

Depends on head qty |

|

water consumption |

15-20m³/h |

|

size |

depends |

|

frequency converter |

Schneider (Germany)/YASKAWA(JAPAN) |

|

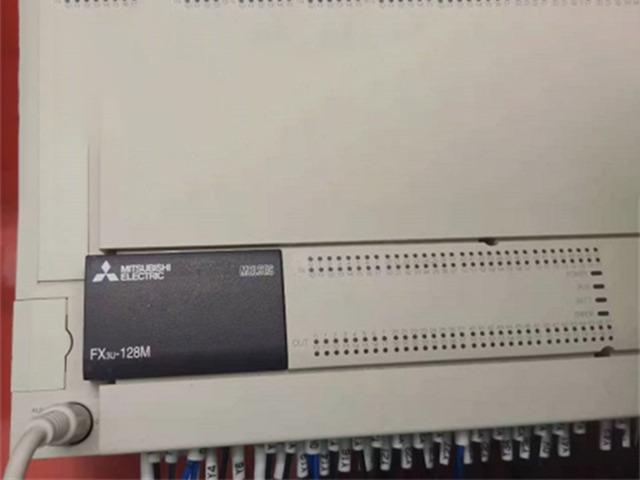

PLC system |

Omron (Japan) |

|

contactor |

Shihlin Electric (Taiwan) |

|

switch |

SIEMENS (Germany) |

Use stone machine polishing granite slab process:

stone polishing is an important process to maintain the stone, some stone can be directly polished, polishing is mainly to increase the brightness of the stone surface. Stone polishing is generally in accordance with the rough grinding → semi-fine grinding → fine grinding → fine grinding → polishing procedures, some can also omit the rough grinding step, mainly to see whether the original stone surface after the initial treatment.

① coarse grinding: the requirement of grinding blade eating knife deep, grinding efficiency, grinding the grain coarse, grinding the surface rougher, mainly to remove the stone in the previous process left saw blade traces and stone flatness, modeling surface grinding in place;

② semi-fine grinding: the coarse grinding traces removed, the formation of new finer grain, so that the stone surface flat, smooth;

③ fine grinding: fine grinding of the stone surface pattern, particles, color has been clearly The surface is fine, smooth, and begins to have a faint gloss;

④ fine grinding: fine grinding of the stone surface, no naked eye perceptible traces. Surface more and more smooth, the highest gloss can reach more than 55 degrees;

⑤ polishing: the use of special granite polishing machine, from No. 50-3000 stone water polishing pad from coarse to fine

Automatic Granite Polishing MachineTechnique Description : I.Suitable for the surface polishing granite/marble II.Using PLC intelligent control system and through the LCD touch s...

1.ProductIntroduction: Stone polisher machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control...

1.ProductIntroduction: Stone polisher machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent con...

Introduction ofgranite polishing machine granite slab polishing machine that can polish the ground stone equipment, can be adapted to different grinding block or grinding pad, thr...

We use wire rope to consolidate Customized Stone Granite Edge Polishing Machine inside container, for diamond tools like saw blade or small cutters or splitters...

Stone machine is closely related to tools and we sell machines as well as giving advice to customers on how to buy diamond tools....

We have rich experience in stone mining and processing, free of charge to provide customers with granite or marble mining and processing solutions, including Cu...