Price: Negotiable

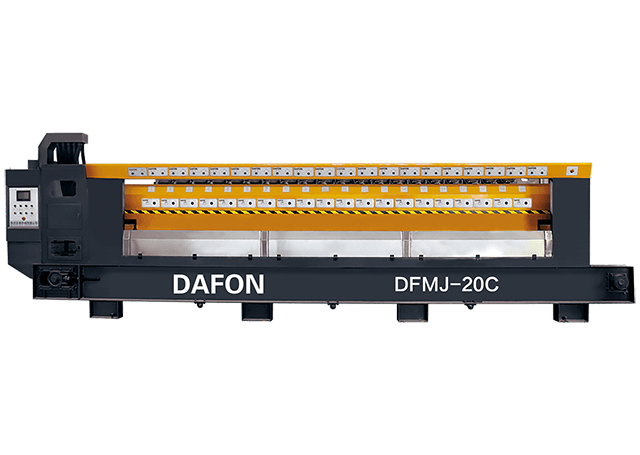

Brand Name: DAFON

Certification: CE, ISO

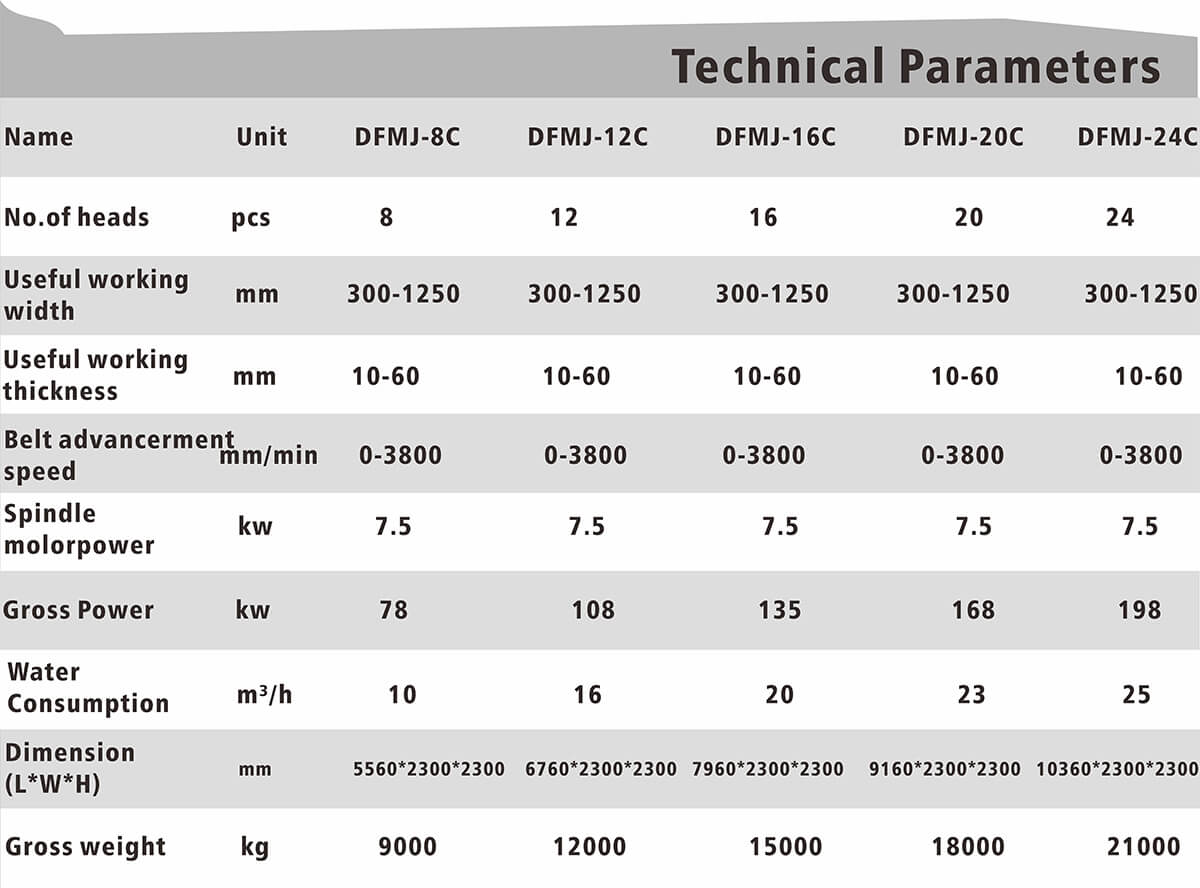

Model Number: DFMJ-16C-24C

Power: Depends on heads no.

Weight: Art & Craft, Stone Industry

Application: Depends on head quantity

Place of Origin: CHINA.

Trading Method: FOB/CIF/EXW Xiamen Port

Minimum Order Quantity: 1 SET

Delivery Time:90 Days

Packaging logistics: In wooded cases with fumigation finish or wrapped with plastic film.

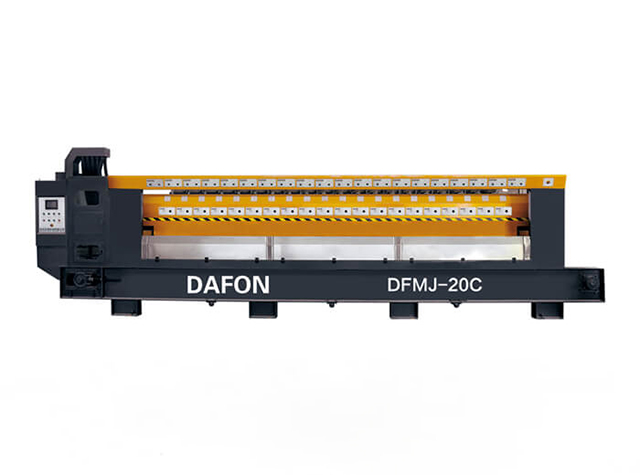

8 heads stone polishing machine; 12 heads line polisher; 16 heads stone polisher machine; 16 heads granite polisher machine; 20 heads stone polishing machine; 24 heads granite line polish machine

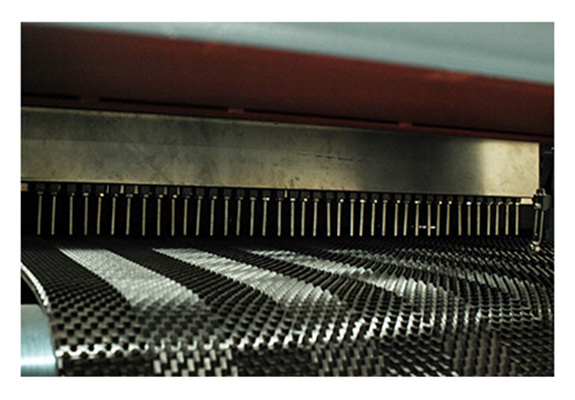

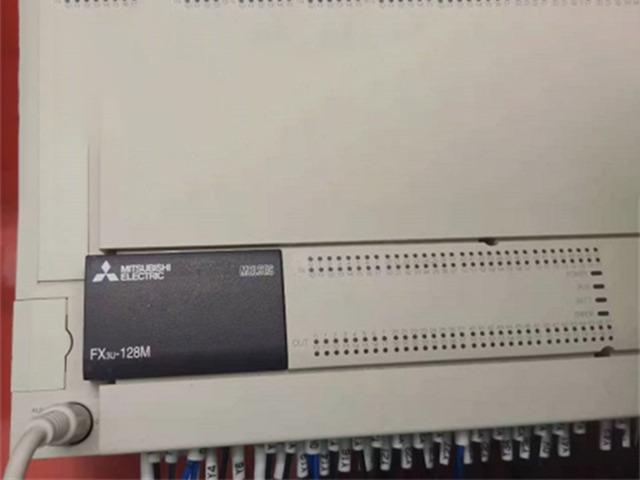

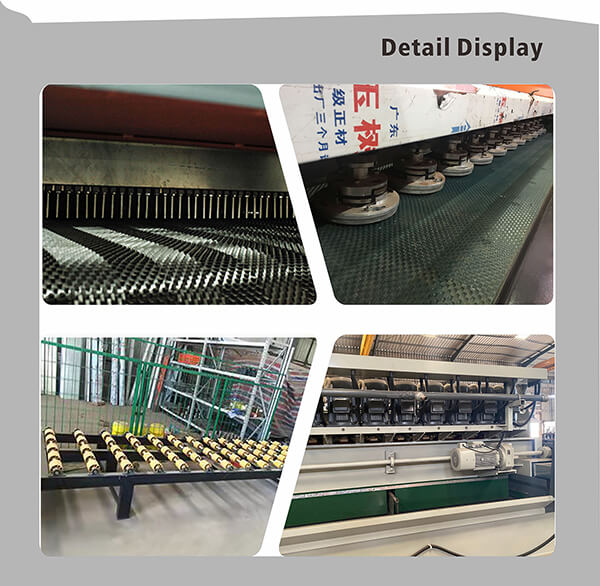

The introduction ofmarble polishing machine Stone polisher machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu o...

Automatic Granite Polishing MachineTechnique Description : I.Suitable for the surface polishing granite/marble II.Using PLC intelligent control system and through the LCD touch s...

1.ProductIntroduction: Stone polisher machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer intelligent control...

1.ProductIntroduction: Automatic granite polishing machineis suitable for polishing Granite slabs or strips. Use the PLC system and liquid crystal display screen menu offer in...

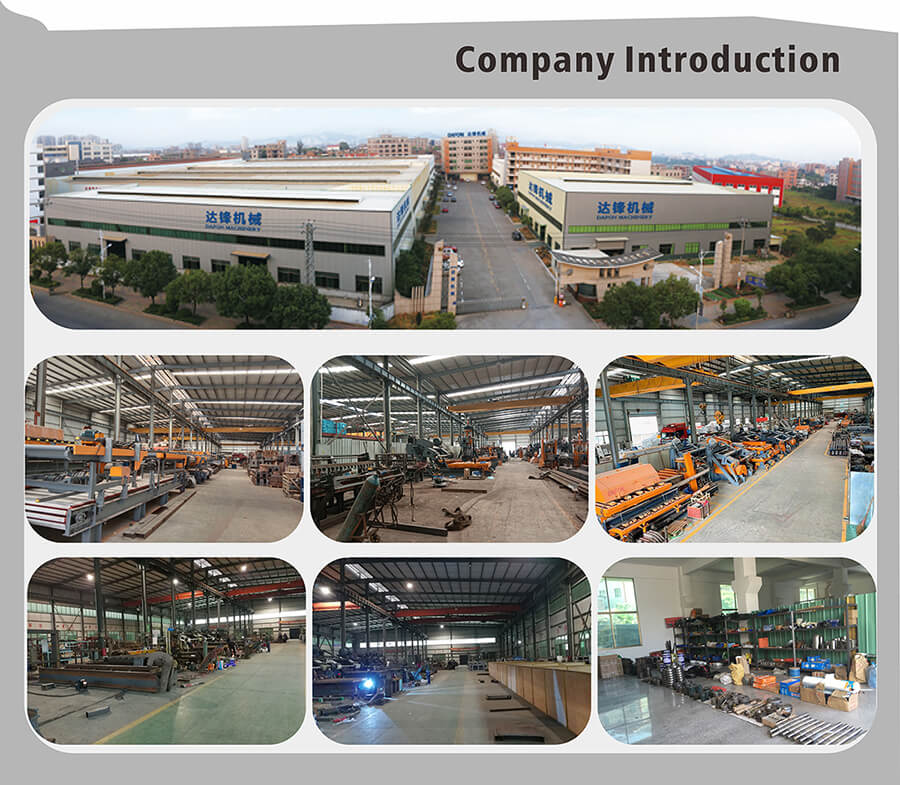

Customized planning of production lines, production of ancillary machines, drawings, installation and production design solutions...

Remote guidance installation Third-party team installation Online software upgrade Regular guidance maintenance Remote troubleshooting Field trouble shooting...

We are able to provide stone machine solutions to our customers in a timely and efficient manner....